Responsible

Professor Hans Ulrik Riisgård, Marine Biological Research Centre, University of Southern Denmark

Aims

In 2010 the MarBioShell-project established a research and demonstration farm for cultivation of off-shore line mussels in Kerteminde Bay (Great Belt) in collaboration with a current partner, the commercial mussel company Nordshell. The plan is to construct and operate a 25% full-scale experimental mussel farm during the years 2010-2011 (cost around 200,000 DKR per year minus anticipated income from the sale of mussels together with tourism activities and eventually sale of the plant when the project period is terminated). The research- and demonstration farm is a unique opportunity for all work packages within MarBioShell to work together in solving an important common task, namely to throw light on the potential, in the broadest sense, to cultivate off-shore line mussels in a rational manner in the Great Belt, thus opening the way for a new trade and employment in this region.

Scientific leaders and participating WPs

- Hans Ulrik Riisgård (WP2)

- Flemming Møhlenberg (WP3 & WP4)

- Jens Honoré Walther ( (WP3)

- Eva Roth (WP5)

- Anne-Mette Hjalager (WP6)

- Niels T. Eriksen (WP1)

Past activities (Nov 2009 - Mar 2012)

In close collaboration with the company Nordshell the following activities on the research and demonstration mussel farm has been performed:

- Reconnaissance and construction of the farm and carrying lines was performed in autumn 2009 and spring 2010 (Fig. 8).

- Growth lines were set out in spring 2010 in order to test for optimization of mussel farm design, calibration of mussel farm models, impact of thinning out on growth and grazing impact and for testing harvest methods. These issues were continued in 2011.

- Net-bags with mussels were hung out and collected from July to October 2010 to investigate bioenergetics and to evaluate the growth potential for line-mussel farming in the Great Belt.

- Mussels were collected from farm-ropes during the winter of 2010/2011 to investigate the effect of temperature on growth and lipid composition and concentration.

- Mussel larvae settling on farm-ropes in the spring 2011 and subsequent growth throughout the season of 2011 has been investigated to supplement our research for evaluation of the potential for line-mussel farming in the area.

- In October and November 2011 growth of mussels in net-bags was followed simultaneously with in situ measurements of current flow and chl a levels in collaboration with DHI to look at the effect of these parameters on growth of mussels and the effect of farm design on the parameters.

- Phyto- and zooplankton data from the last 10 years is being analysed in order to evaluate the importance of heterotrophic relative to phototrophic plankton organisms in blue mussel diets in the field.

- Organization, innovation, branding and regional development

Ongoing activities

The concept of growing mini-mussels in one season is being evaluated as a potential strategy for producing line-mussels in the Great Belt.

Some supplementary comments

The research- and demonstration mussel farm was established in 2010 in the southern part of Kerteminde Bay, close to the Great Belt and near Risinge Hoved, with a distance of two nautical miles from the Marine Biological Research Centre (SDU) at the harbour of Kerteminde which is also the port from where the mussel farm is being operated. The mussel farm covers an area of 175 × 250 m. It consists of 15 long-lines with 1.000 m of on-growing rope on each long line. The output is estimated to be approximately 4 kg mussel per metre about 1 to 1.5 years after the first settling of mussel larvae. The mussel culture has been established in close cooperation with the present MarBioShell-partner, Nordshell which has the necessary experience and the equipment needed. The same partner also do service and running operations, and is responsible for the harvest of mussels. The partner has, due to many years in the business well-established contacts to other mussel farmers (domestic and overseas), the mussel industry and equipment suppliers.

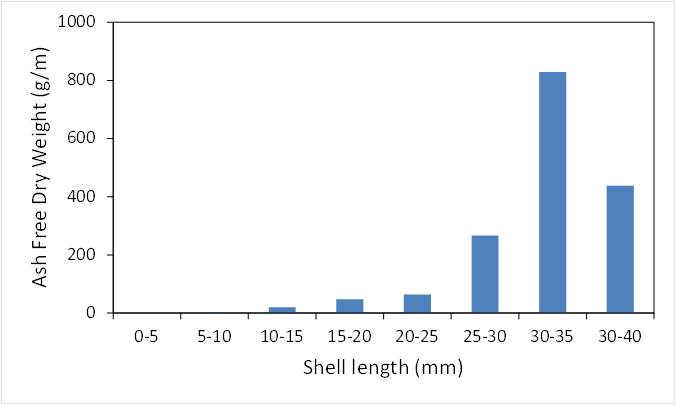

Outcome of harvest in 2010 and 2011 showed that the predicted biomass of 4 kg/m was exceeded 3.5 times; hence in October between 11 kg and 14 kg wet weight was present per meter rope, from surface to at least 6 m depth. The growth was especially fast during autumn and was fuelled by high currents (average at 21 cm/s in surface waters) and high concentration of chlorophyll a in surface waters from the western Baltic Sea. In October mussels larger than 30 mm accounted for 75% of the biomass (Fig. 12). Ash free dry weight constituted 15% of wet weight (normally 6% in natural populations) underlining that meat content was very high.

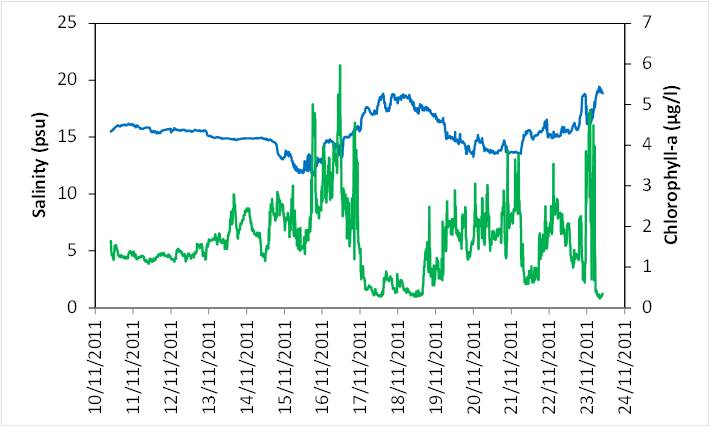

The capacity of Great Belt to support mussel growth in rope cultures relies on a consistent and long-lasting autumn bloom in the western Baltic Sea. Monitoring in the Great Belt in 2009 and 2010 did show increasing chlorophyll-a levels from early August to early December averaging 3 µg/l. High frequency measurement at the mussel farm showed that high chlorophyll a levels were associated with falling salinities (i.e. higher contribution of waters from the western Baltic Sea) and decreasing levels at rising salinities (from Kattegat), see Fig. 13.

In connection to the rope culture and the closely associated research activities it may also be possible develop a range of other related activities to be examined in more details by WP6. This could be tours for tourists in cooperation with the nearby Fjord & Belt Centre (Kerteminde) which is a self-governing marine research and experience centre with some 60.000 visitors every year. Other possibilities are events with local restaurants and the local fishery, and Kerteminde is well-known for its long tradition for fisheries and seafood industry.

Fig. 10. The MarBioShell research- and demonstration farm for line-mussels was established in 2010 in Kerteminde Bay (Great Belt).

Fig. 11. Farm-ropes with mussels in the MarBioShell farm, October 2011.

Fig. 12. Ash Free Dry Weight (without shells) of mussels harvested in October 2011.

Fig. 13. Temporal variation in salinity and chlorophyll-a in the mussel farm during 14 days in November 2011.

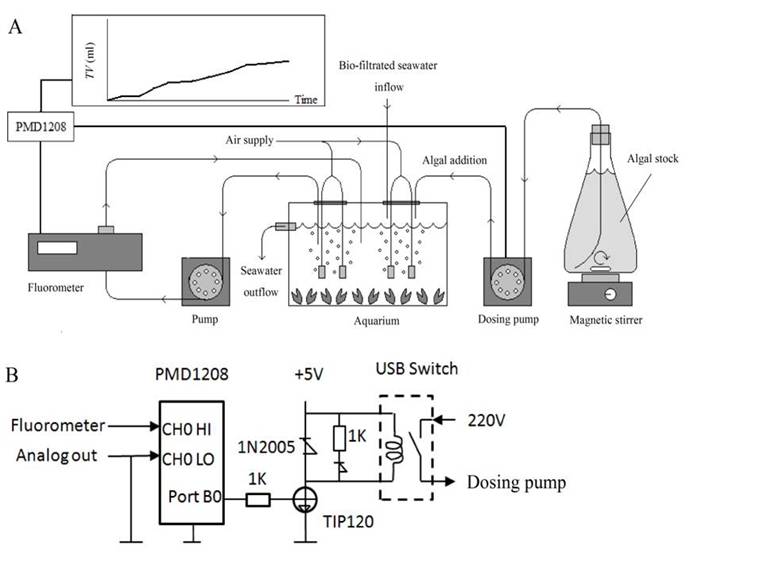

Fig. 14. Fluorometer-controlled apparatus for continuous measurement of filtration rate of mussels at constant algal concentration (9).